From Confirming Requirements to Mold Production: A Step-by-Step Reveal of the Customized Tableware Development Process

In an increasingly competitive restaurant market, relying solely on taste and price is no longer enough to make a brand stand out. Modern consumers pay more attention to the overall dining experience, including the sensations conveyed by utensils and tableware. For restaurant owners, “customized tableware” not only meets customers’ practical needs but also serves as a powerful tool to showcase brand value and image. Each step—from initial concept to mass production—affects the final product’s quality and character. Drawing on years of development experience at Tair Chu, the following explains the complete customization process to help you stand out in the market.

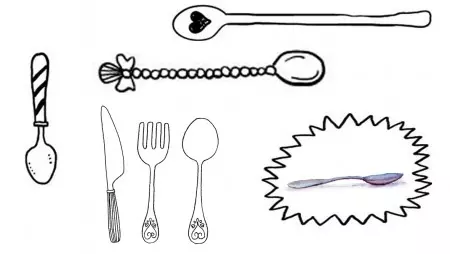

1. Requirements Confirmation and Conceptualization

Before starting the development of customized tableware, the first task is to clarify your brand positioning and usage scenarios, and to turn your ideas into tangible concepts through thorough, two-way communication. Restaurant owners can prepare hand-drawn sketches, reference samples, or even clay models to convey the desired appearance and function of the tableware. At this stage, consider the following:

Brand Positioning: Are you focused on fine dining or a more casual, friendly style? Different brand images require distinct design approaches for the tableware.

Functional Needs: What types of dishes will the tableware accompany? For example, a spoon’s depth or fork’s tines can be adjusted for specific foods.

Reaching Consensus: By communicating closely with the manufacturer, both parties can agree on details such as materials, temperature ranges, and expected service life. This sets a solid foundation for subsequent design and production.

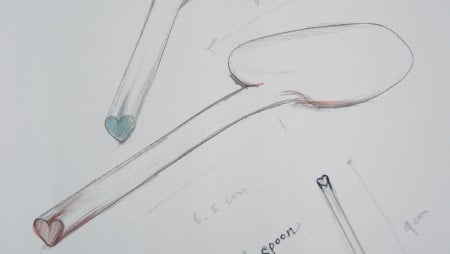

2. Drawing Designs and Revisions

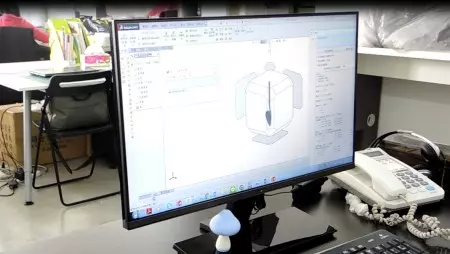

Once the requirements are clear, the manufacturer will start creating 2D and 3D drawings to transform the initial concept into a visual design blueprint.

Drafting the Drawings: Usually takes about 10-14 business days. The more complex the design, the longer it may take.

Design Feedback: At this stage, restaurant owners can provide feedback on length, thickness, and grip comfort. The manufacturer will adjust accordingly.

Drawing Confirmation: Reviewing multi-angle 3D renderings ensures both visual appeal and practical usability. After several rounds of modifications, the final design is confirmed.

3. Prototype Testing and Functional Verification

If you have concerns about appearance or functionality, you can choose to create prototypes for testing:

3D Printing: Fast but with lower precision and strength, suitable for a preliminary look at the appearance.

CNC Machining: Produces samples highly similar to the final product, making it easier to evaluate shape and grip.

Sample Mold: Although more expensive, it yields samples nearly identical in appearance and strength to the final mass-produced items, making it suitable for brands with high demand.

This stage allows you to confirm the tableware’s strength, comfort, and functionality, ensuring the final product meets expectations.

4. Finalizing Materials, Colors, and Surface Treatment

After confirming the design, select appropriate materials and colors, and decide on the surface treatment:

Material Selection: Choose materials based on the characteristics of the dishes and usage conditions.

Color Confirmation: Determine the exact color using real samples or Pantone color codes to ensure accurate brand hues.

Surface Treatment: High-gloss finishes highlight a premium feel, while fine textures add unique tactile qualities and prevent slipping.

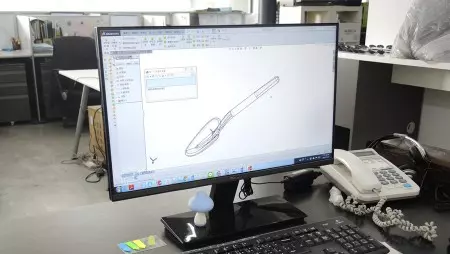

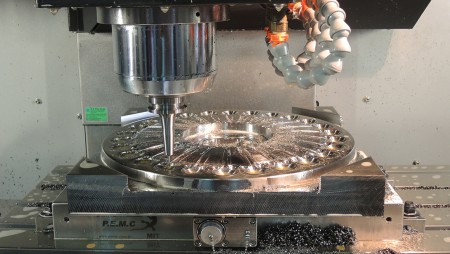

5. Creating Production Molds and Trial Production Confirmation

It generally takes about 28-35 business days to complete the first trial production of the molds or fixtures:

Test Production: Confirm that the mold operates correctly and that product details match the design. Surface treatment is also completed at this stage.

Ready for Mass Production: If improvements are needed, this is the time to make final adjustments, ensuring stable quality when mass production begins.

6. Final Mass Production and Quality Control

After the molds are completed, full-scale production can start:

Multi-Layer Inspection: Includes initial sample checks, in-process inspections, and pre-shipment checks to ensure consistent product quality for every batch.

Stable Quality: Through a comprehensive inspection process, customized tableware truly becomes a factor that enhances customers’ dining experience.

Q: What if I do not know how to use design software? Can I still create customized tableware?

A: Yes. Even if you only have hand-drawn sketches or clay models, the manufacturer can complete the drawings based on your ideas and provide expert suggestions on materials, dimensions, and functionality.

Q: Is making prototypes necessary?

A: Not always. If you are unsure about the shape or function, making prototypes is recommended to ensure the final product meets your expectations.

Q: Can I change the color at any time?

A: Adjustments can be made through actual samples or Pantone color references before mass production begins. Once production starts, the color is fixed.